The market for electric vehicles is booming. Simultaneously, new solutions are being sought to increase driving range, shorten charging times, increase safety and improve sustainability. Solid-state batteries have the potential to replace conventional liquid electrolyte-based Li-ion batteries in the future. Until then, there are still some challenges to be mastered and many tests to be carried out. As there are currently no uniform standards in this field, weisstechnik is using its many years of experience to develop solutions for compact test cabinets and test laboratories that will reliably meet all future requirements.

The development race has begun

The race to find the best solution for solid-state batteries began long ago. Depending on the manufacturer, the first production cars should roll off the assembly line between 2025 and 2030. Yet so far, only the French company Blue Solutions has presented a solution ready for series production and used in vehicles such as the Mercedes eCitaro. Companies from Japan, South Korea, China and the USA are currently the main drivers of innovation. Given their many years of experience in automotive development, however, German companies are ideally placed to make decisive contributions to the success of solid-state batteries. Testing technology from weisstechnik can play an important role in this.

Solid-state battery innovations

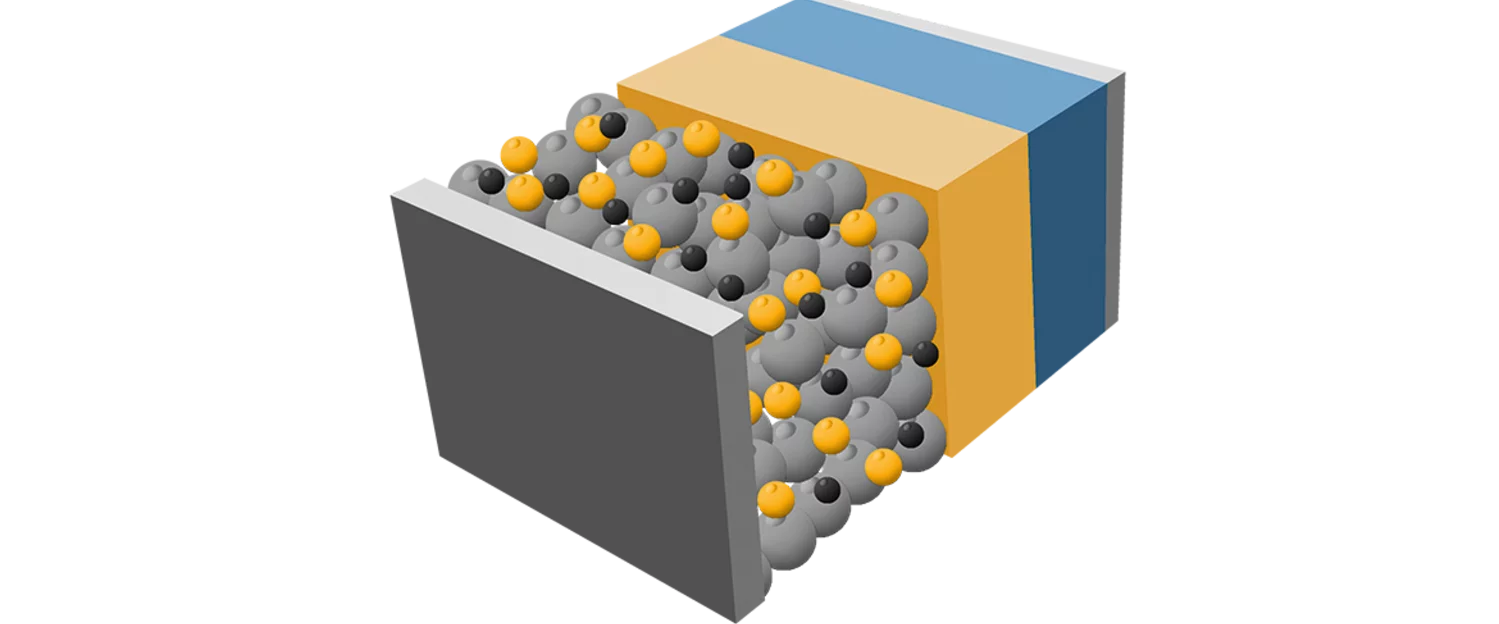

In contrast to conventional Li-ion batteries with liquid electrolytes, solid-state batteries (SSB) work using solid electrolytes. Currently, different solid electrolyte classes are being researched with regard to their performance in full SSB cells. The focus is primarily on oxide-, sulphide-, polymer- and halide-based solid electrolytes and the hybrid solutions that can be derived from them. The battery chemistry has to be redeveloped across all lines of development and every component has to be perfectly matched in order to achieve the desired properties. For instance, new anode active materials (AAM) such as lithium metal and silicon could also be used. Several options are also being explored regarding cathode active materials (CAM).

Impressive advantages are achievable

Numerous research projects are working on the assumption that the ideal combination of materials in solid-state batteries will offer significant advantages over liquid electrolyte-based Li-ion batteries and can revolutionise the world of electromobility over the long term. Solid-state batteries promise a significantly higher energy density and a longer range of up to 30 % while also being more compact. Depending on the cell chemistry, the charging time can also be significantly reduced and the number of charging cycles can be increased to over 2,000. The cell chemistry also contributes to the low fire risk of solid batteries in the event of a thermal runaway caused by overcharging or an accident, as no flammable, liquid components can leak out. They can also be produced in a much more sustainable way and therefore have considerable future potential. However, the production of the components and the cell production must be made scalable and the production costs, which are currently 7 to 8 times higher, must be reduced to a level suitable for series production.

Development pressure is enormous

Solid-state battery technology is currently being researched by vehicle manufacturers, suppliers, development laboratories and universities. There is considerable funding available for this - VW alone is investing 300 million euros over the next few years through its partner QuantumScape. In Germany, Fraunhofer Institutes and the KIT, as well as the Forschungszentrum Jülich, the TU Braunschweig and the MEET in Münster, among others, are committed to addressing this issue. Innovations are also being driven by the interdisciplinary Zentrum für Materialforschung (ZfM) (Centre for Materials Research) at the Justus Liebig University in Gießen. With his team of around 40 people, the internationally renowned specialist Prof. Dr. Dr. h. c. Jürgen Janek is conducting research into the chemical and physical principles and challenges of solid-state batteries. He also coordinates the activities of the Competence Cluster for Solid State Batteries (FestBatt), which is integrated into the umbrella concept “Battery Research Factory” of the Federal Ministry of Education and Research (BMBF). “The expectations in the market are huge, the pressure to deliver fast solutions is enormous. It is therefore important to work with testing technology that delivers reliably precise results,” explains Prof. Dr. Dr. h. c. Jürgen Janek, Executive Director of the ZfM and coordinator of the FestBatt cluster.

Testing technology as a factor for success

The pressure on development is also increasing the demands on test technology providers. This is because even solid-state batteries must undergo numerous tests before they are ready for series production. While we can assume that their material properties make them less problematic than conventional Li-ion batteries. They also have a higher energy density and, therefore, a different hazard potential, which means adapting the testing technology for safety devices. Only then can performance and security be comprehensively tested. However, as there is still no application-related test standard or manufacturer's specifications, the question arises; Which tests are necessary and with which requirements and which test facilities can do this reliably and safely? Despite their presumably lower hazard potential, toxic and explosive hydrogen sulphide (H2S) outgassing is still possible while testing sulphide-based solid-state batteries. Therefore, test systems must be designed to prevent hazards to people, test equipment and the environment.

Requirements for testing technology

In addition to the possible danger of H2S outgassing, test facilities must also take into account the higher operating temperatures that solid-state batteries sometimes require. Regardless of the unique characteristics mentioned above, we expect test facilities for solid-state batteries to have the same or similar testing requirements and environments as conventional Li-ion batteries. The contents of the standards will gradually become clearer as developments progress. This is crucial for ensuring that everyone within this dynamic field has a reliable and consistent foundation for delivering comparable test results.

Upgrades for existing systems

Many companies and institutions already have testing facilities for conventional Li-ion batteries. In most cases, those from weisstechnik can be easily converted or upgraded to test solid batteries. For example, a test chamber may only require the integration of an H2S detection device with sensor and warning lamp and, if necessary, an additional ventilation solution. Even ClimeEvent test chambers for laboratory applications can be quickly and easily retrofitted to meet most requirements. Upgrading existing testing solutions is more sustainable and quicker for companies. This gives users an essential competitive advantage in the highly dynamic field of development, where the aim is to find meaningful answers and present secure solutions as quickly as possible.

New test cabinets and chambers

Many young companies and start-ups are also researching solid-state batteries in addition to the numerous established companies and institutions. They often lack or have only limited test facilities of their own and are therefore dependent on test cabinets and test chambers that are available at short notice and safe to use. Weisstechnik offers an uncomplicated solution to this problem The requirements for test equipment can be easily determined with the existing module kit for hazard levels and, after a risk assessment, can be implemented into standardised solutions or individual custom-made products. The basic modular concept of weisstechnik's test solutions simplifies and accelerates their quick design and delivery.

Testing technology remains a matter of trust

When it comes to choosing a partner for testing solutions in the automotive sector, competence, experience and service are key criteria. weisstechnik are experienced specialists in sophisticated testing solutions and have been active in the field of Li-ion batteries for more than 20 years. This knowledge enables the company to offer future-proof testing solutions that can be implemented in the short term and pay off over the long term. As an innovation leader in the industry, weisstechnik provides companies with proactive and highly flexible service support through a nationwide service network and tailored service contracts. This increases operational safety and allows companies to concentrate on their development work.

1.291 words. Reprint free of charge. Please state Weiss Technik as the source.