Weiss Technik Nederland B.V.

Newtonstraat 5, 4004 KD Tiel, Nederland

Hygiene requirements in the food industry are high. Nevertheless, the branch has great problems with viruses, bacteria and mould from time to time. This is caused in part by the climate conditions in the plants. An optimum hygienic air conditioning technology makes reliable protection possible.

Can air conditioning technology spread viruses like coronavirus?

Yes, because aerosols are considered to be one of the main ways coronavirus is transmitted. Coronavirus can survive for a long time in closed rooms with cooled air and high air humidity. Air conditioning systems which maintain air circulation quickly transport virus-charged aerosols even over longer distances and can contribute to the virus spreading if there is no appropriate safety concept in place. This applies to slaughterhouses as well as fish and dairy processing companies where similar conditions prevail. Since air conditioning systems are important for product safety, solutions are required which reliably kill viruses and germs or make them harmless.

How does the 4+1 safety concept provide protection from pathogens?

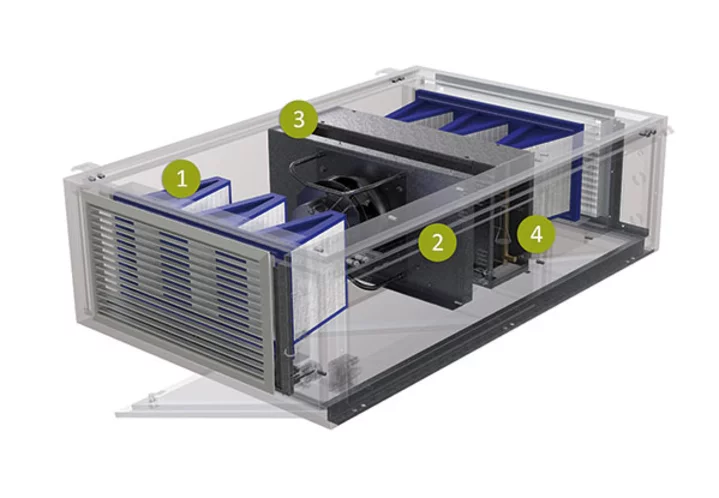

The 4+1 concept is effective against coronavirus as well as against bacteria and mould. A high-efficiency particle filter filters 99.995 % of all airborne particles out of the air during operation. The micro-organisms trapped by the filter are killed by UVC radiators. The anti-microbial coating of the inner plates confines micro-organisms to an even greater extent on the surfaces. During the hygienically sensitive downtimes of recirculating air devices, thermal disinfection takes effect and prevents a biofilm forming which would be an ideal breeding ground for micro-organisms of all kinds. Our air purifier module, which removes volatile hydrocarbon compounds – so-called Volatile Organic Compounds – from the air, provides additional protection for the food industry. These VOCs cause unpleasant odours and have a negative impact on food quality.

What expertise does weisstechnik have to offer in the field of hygiene air conditioning?

We have been dealing with the subject of infection prevention for more than 40 years now. Ever since then, we have been equipping operating theatres and other areas in hospitals with air conditioning technology. These areas have maximum safety standards concerning air hygiene in order to safely protect patients and personnel from hazards by airborne micro-organisms. This makes the solutions we originally designed for the medical sector suitable for meat, fish and dairy processing plants, too, which are having to give some thoughts to new hygiene measures during the corona pandemic in order to better protect their personnel and products.

One of our products to employ the safety concept is our hygiene air conditioning unit Vindur® Top, a recirculating air solution for rooms occupied by persons. We can develop customer-specific versions depending on requirements.

Infection-related shutdown threatens the existence of every company. Our 4+1 safety concept kills viruses, bacteria and mould effectively and thus makes a major contribution to stopping this happening. It protects employee health, guarantees food quality and protects companies from the economic losses and damage to their image related to a shutdown.

Especially strict hygiene directives in accordance with VDI 6022 apply for the ventilation and air conditioning equipment of rooms occupied by persons. Alongside wards and examination rooms in the medical sector, these include production areas as well as break and rest rooms in industry. Our hygiene air conditioning solutions with 4+1 safety concept fulfil these high hygiene requirements and thus ensure hygienic room cooling meeting both standards and specific demands.

Our hygiene air conditioning solutions with 4+1 safety concept are ideal for use in food-processing plants. In canteens, personnel rooms or changing rooms they protect employees from infection by airborne viruses. In production halls, slaughter areas and packaging departments they do not only protect employee health, they also provide safe protection of the products from contamination with viruses, bacteria and mould.

Interested?

Contact us!

If you are interested in a hygiene air conditioning solution for the food-processing

industry we will be happy to advise you and develop a tailor-made solution for your requirements.

Your contact:

Rupert Mack

Head of Strategic Business Area MediClean

Tel. +49 172 6868 263

rupert.mack@weiss-technik.com

Newtonstraat 5, 4004 KD Tiel, Nederland